Tel: +86-577-86801027 / E-mail: cooper@lianhevf.com

Stainless Steel Fitting

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-07 Origin: Site

You may be surprised by how strong a stainless steel flange is. This material is different from others because it can handle high pressure. It also works well in high heat and in places where things can rust. It does not lose its strength or trustworthiness.

You get piping systems that are safe and work well. They do not leak.

Flanges give pipes the strength and flexibility they need in hard situations.

Picking stainless steel flanges helps stop problems and keeps your system running smoothly.

Stainless steel flanges are very strong and do not rust easily. They work well in places with high pressure and heat. Picking the right type and grade of stainless steel flange keeps piping systems safe. It also helps stop leaks from happening. Cleaning and checking seals often can make stainless steel flanges last longer. This also helps systems work better. Stainless steel flanges can cost more at first. But they save money over time because they last long and need little care. Stainless steel flanges are good for the environment. They can be recycled and help cut down on waste in many industries.

A stainless steel flange joins pipes, valves, and equipment together. It helps make a strong and tight connection. This part lets you take pipes apart for fixing or cleaning. It also gives your system more strength and keeps it steady. This is very helpful when there is high pressure or heat.

There are many types of stainless steel flanges you can pick. The most used types are:

Slip-on flange

Weld neck flange

Blind flange

Threaded flange

Socket weld flange

Each type is made for different jobs. For example, weld neck flanges are good for high-pressure pipes. Socket weld flanges work best with small pipes.

You also need to choose the right grade. The two main grades are 304 and 316. Here is a simple table about them:

| Grade | Composition | Advantages | Applications |

|---|---|---|---|

| 304 | 18% Chromium, 8% Nickel | Resists rust, easy to shape | Food, water pipes, chemical plants |

| 316 | 16% Chromium, 10% Nickel, 2-3% Molybdenum | Better at fighting rust, good with saltwater | Marine, medicine, oil and gas |

You will see codes like ASTM A182 and ASME B16.5 on most stainless steel pipe flange products. These codes show that your ss flange is safe and high quality.

Stainless steel flanges are used in many fields. They are found in oil and gas, chemical plants, water treatment, and shipbuilding. Here are some common uses:

High-pressure pipes in oil and gas

Moving chemicals in factories

Clean water and wastewater systems

Marine jobs that need to fight saltwater

Making medicine in factories

Tip: Stainless steel flanges help your system stay strong and not leak, so it stays safe.

You might ask why a stainless steel flange is so strong. The answer is in the mix of metals it uses. Stainless steel flanges have different elements that work together for strength. Here is a table that shows what is inside a typical stainless steel pipe flange and how each part helps:

| Element | Minimum/Maximum | Contribution to Mechanical Strength |

|---|---|---|

| Chromium (Cr) | Minimum 10.5% | Enhances corrosion resistance |

| Nickel (Ni) | Minimum 8% | Contributes to overall strength and ductility |

| Carbon (C) | Maximum 1.5% | Affects hardness and strength |

| Molybdenum (Mo) | Often included | Improves resistance against reducing acids and pitting in chloride-rich environments |

Chromium helps the flange fight rust. Nickel makes the flange tough and lets it bend without snapping. Carbon makes the flange harder and stronger. Molybdenum gives extra help in salty or rough places.

How you make a flange is important too. Forging shapes the metal with heat and pressure. This makes the metal grains tighter and stronger. Here is a table that shows how forged stainless steel is different from cast stainless steel:

| Property | Forged Stainless Steel | Cast Stainless Steel |

|---|---|---|

| Tensile Strength | 580 MPa | 485 MPa |

| Yield Strength | 1170 MPa | N/A |

| Fatigue Limit | ~200 MPa | N/A |

| Density | >99.9% | N/A |

Forged flanges, like weld neck or socket weld flanges, can take more force and last longer. They are strong and tough. These flanges can handle lots of pulling and pushing. You can use thicker flanges for higher pressure. This means your ss flange will not break or bend, even in hard jobs.

Note: Some new flanges use duplex or super duplex stainless steel for even more strength. Others use CNC machines or 3D printing for better shapes and performance.

You want your flanges to last, even with water, chemicals, or salty air. Stainless steel flanges do not rust like carbon steel or cast iron. Chromium is the reason. When there is more than 10% chromium, a thin layer forms to stop rust and protect the metal.

Rust can make metal weak and easy to break. If a flange rusts, it can lose strength or snap. Stainless steel flanges stay strong because they do not rust fast. This makes them great for oil and gas, chemical plants, and places with water or steam.

Stainless steel flanges fight rust better than most.

They are strong and work well in hot or high-pressure places.

They are perfect for oil and gas, chemical plants, and medicine factories.

You can help your flanges last longer with good care. Wash them with mild soap and warm water. Check bolts and seals often. Use special grease on the joints. These steps keep your flanges safe and strong for a long time.

Tip: If you want something that lasts, pick a stainless steel flange for your next job. It is strong, does not rust, and will last many years.

When you look at stainless steel flanges and other types, you notice big differences. Stainless steel flanges are strong and do not rust easily. They can handle high heat and lots of pressure. The table below shows how different flange materials compare:

| Material Type | Properties and Advantages | Applications |

|---|---|---|

| Stainless Steel Flanges | Excellent corrosion resistance, high strength, withstands high temperatures and pressures | Chemical, petrochemical, food and beverage, etc. |

| Carbon Steel Flanges | Known for strength and durability, can be heat-treated, susceptible to corrosion | Oil and gas, power generation, water treatment |

| Alloy Steel Flanges | Enhanced strength, toughness, and wear resistance | Oil refineries, power plants, chemical processing |

| Duplex and Super Duplex Stainless | Higher strength than austenitic grades, excellent corrosion resistance | Oil and gas, marine applications, chemical processing |

| Nickel Alloys (Inconel, Monel) | Exceptional resistance to extreme temperatures and corrosive environments | Chemical processing, aerospace, marine, nuclear |

| Copper and Brass Flanges | Good corrosion resistance, lightweight, easy to install | Water systems, HVAC applications |

Stainless steel flanges are strong and do not rust fast. Carbon steel flanges are cheaper, but they rust more and need extra care. Duplex stainless steel and nickel alloys are even stronger, but you only need them for special jobs.

Tests show stainless steel flanges are hard and strong. A hardness test gives a number between HRB 70 and 90 for a 304 ss flange. A tensile test shows strength over 520 MPa and stretching over 40%. These numbers mean your flange will not break or crack easily.

You want your pipes to last and work well. Stainless steel flanges work better than many others in tough places. They keep their shape and strength in high heat and pressure. You can use them with chemicals, steam, or saltwater.

Stainless steel flanges do not rust and work in hot places.

You can use them in food, medicine, and chemical factories.

They work in very cold and very hot jobs.

Stainless steel flanges last longer and need less care. Look at the table below:

| Material Type | Lifespan (Years) | Maintenance Level |

|---|---|---|

| Carbon Steel Flanges | 15–25 | Basic maintenance needed |

| Stainless Steel Flanges | 25–50 | Minimal maintenance required |

Carbon steel flanges cost less at first, but you pay more later for repairs. Stainless steel flanges cost more at the start, but you save money because they last longer and need less work.

Stainless steel flanges are also good for the environment. They can be recycled 95% of the time. Most old stainless steel is made into new things. This saves resources and energy. You use less new material and make less waste.

Tip: If you want something strong, long-lasting, and good for the planet, pick a stainless steel flange for your next job.

Stainless steel flanges are used in many jobs. They help different industries because they last a long time. If you pick a corrosion resistant stainless steel flange, your system works better and lasts longer. Many companies in oil and gas, water treatment, and chemical plants now use these flanges. They have seen big changes and better results.

Here is a table that shows what industries get from using stainless steel flanges:

| Benefit | Description |

|---|---|

| Improved Sustainability | CNC machining uses less material and makes less waste. Scrap can be recycled. |

| Cost Savings | Companies save money because the flanges are strong and reliable. |

| Enhanced Precision | Special tools and software make sure each flange fits perfectly. |

| Operational Efficiencies | Making flanges is faster and costs less with better processes. |

These flanges help you save money and protect nature. Oil and gas companies have fewer leaks and joints last longer. Power plants trust these flanges because they work well with high heat and pressure. The next table shows which industries see the most improvement:

| Industry | Improvement in Reliability |

|---|---|

| Oil and Gas | Fewer leaks and better sealing with strong flanges. |

| Petrochemical | Flanges work well even in hard and busy places. |

| Power Generation | Flanges last longer and work well under pressure. |

Note: Some reports say stainless steel and duplex flanges do great in tough places. For example, they work well in the Johan Sverdrup oil field, where it is very cold and the pressure is high.

Stainless steel flanges give you more than just pipe connections. They have extra benefits that make your job easier and safer.

Here are some perks you might notice:

You do not need to fix them often, so you save time and money.

Recycling is easy, so you help the earth by making less waste.

Stainless steel does not burn easily, so it keeps your system safe.

The smooth surface helps keep water and food clean.

These flanges can take high pressure, so they work in oil and gas pipes.

You can weld them well and put them in easily, even with blind or threaded flanges.

They are tough and do not break easily, even if handled roughly.

You will see these flanges in water plants and chemical factories. Their strength and resistance make them a smart pick for hard jobs.

When you choose a stainless steel flange, you need to think about several important factors. Picking the right flange helps your system work safely and last longer. Here are some things you should look at:

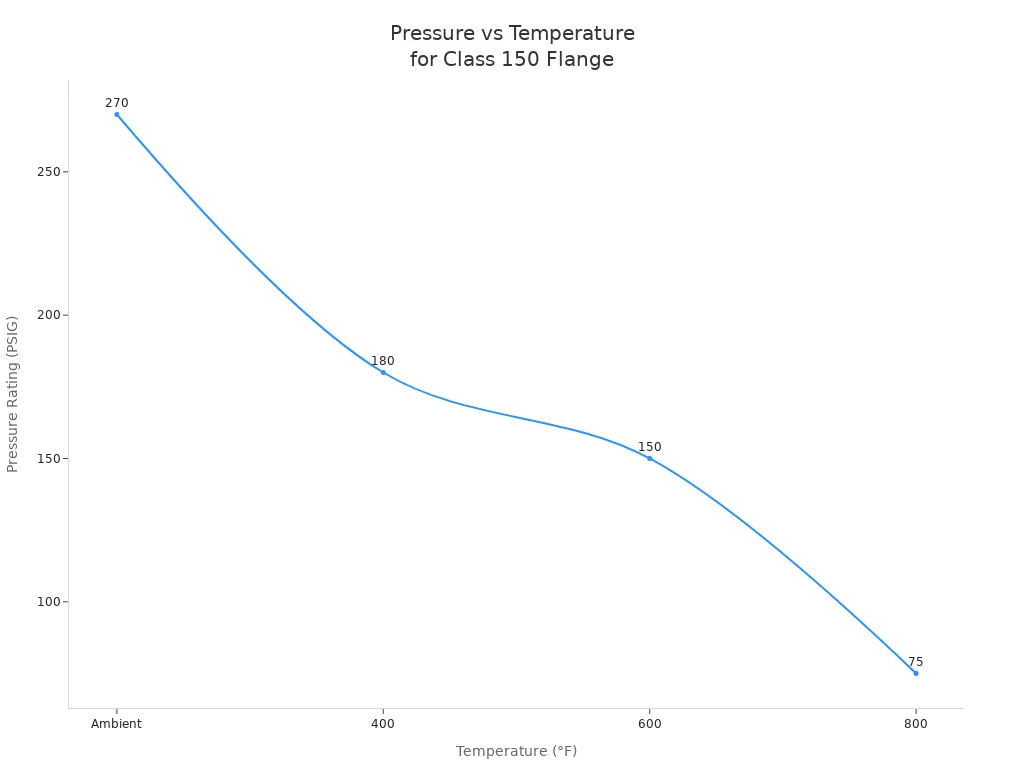

Pressure and Temperature Needs: High-pressure or high-temperature jobs need strong flanges like weld neck or blind flanges. Pressure ratings tell you how much force a flange can handle. These ratings change with temperature. For example, a Class 150 flange can take 270 PSIG at room temperature, but only 75 PSIG at 800°F.

| Flange Class | Pressure Rating (PSIG) | Temperature (°F) |

|---|---|---|

| Class 150 | 270 | Ambient |

| Class 150 | 180 | 400 |

| Class 150 | 150 | 600 |

| Class 150 | 75 | 800 |

Material and Compatibility: Make sure the flange material matches your pipe. Stainless steel is a good choice because it is resistant to rust and chemicals.

Type and Design: You can pick from socket weld, flat, or welded neck flanges. Each type fits different jobs.

Industry Standards: Look for flanges that meet standards like DIN, ANSI, or JIS. These standards help you get safe and reliable parts.

Durability and Maintenance: Choose a flange that needs little care, especially if you work in a place where repairs are hard.

You should also think about cost. Stainless steel flanges cost more at first, but they last longer and need less fixing. Over time, you save money because you do not have to replace them as often.

Stainless steel flanges work well in many places, but you should know about some limits:

You may need more space for flanged pipe systems.

Insulating pipes with flanges can cost more.

Flange connections can leak if you do not install them right.

The first price for stainless steel is higher than for carbon steel, but you get better value over the life of the product.

| Material Type | Initial Cost | Maintenance Cost | Lifecycle Value |

|---|---|---|---|

| Carbon Steel S355 | Lower | Higher | Less Attractive |

| High Strength Carbon S460 | Moderate | Moderate | Moderate |

| Duplex Stainless Steel EN 1.4162 | Higher | Lower | More Attractive |

Tip: Always check the space you have and the cost of insulation before you choose a flange. Make sure you install flanges carefully to avoid leaks.

You should weigh the upfront cost against how long the flange will last. If you want a strong, resistant, and low-maintenance option, stainless steel flanges are a smart pick for most jobs.

You can trust stainless steel flanges for your toughest jobs. These flanges give you strength and corrosion resistance. They keep your piping systems safe and leak-free, even in extreme conditions. You will find them in oil and gas, food processing, and HVAC because they last a long time.

Corrosion resistance means fewer repairs.

High strength keeps your system working.

Reliable performance saves you money over time.

Choose stainless steel flanges for value, safety, and long-lasting results.

Stainless steel flanges use a mix of metals like chromium and nickel. These metals give you high strength and help the flange resist bending or breaking. Forging also makes the flange tougher.

Tip: Choose forged stainless steel for the best strength.

You get great protection from rust because stainless steel has chromium. This metal forms a thin shield that stops rust and corrosion. You can use these flanges in wet or salty places without worry.

You pay more at first for stainless steel flanges. You save money over time because they last longer and need less fixing. You get better value for your project.

| Material | Initial Cost | Maintenance Cost |

|---|---|---|

| Stainless Steel | Higher | Lower |

| Carbon Steel | Lower | Higher |

You line up the flange with your pipe. You use bolts to connect them tightly. You check the seal to stop leaks. You can weld some types for extra strength.

Note: Always follow safety rules when you install flanges.