Tel: +86-577-86801027 / E-mail: cooper@lianhevf.com

Stainless Steel Fitting

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: Site Editor Publish Time: 2025-10-10 Origin: Site

You might wonder what makes stainless steel flange different from carbon steel flange. Stainless steel flange does not rust easily. It can handle harsh places. But it costs more money. Carbon steel flanges are good for simple jobs. They help you save money at first. Here is a quick chart to compare them:

| Feature | Stainless Steel Flange | Carbon Steel Flange |

|---|---|---|

| Corrosion Resistance | High | Low |

| Strength | Strong | Good |

| Temperature Tolerance | Excellent | Moderate |

| Cost | More expensive | Less expensive |

| Maintenance | Low | High |

You will see easy tips here. These tips help you choose the best flange for your project.

Stainless steel flanges do not rust easily. They also do not corrode. This makes them good for tough places. Chemical plants and marine jobs use them a lot.

Carbon steel flanges cost less at first. But they need more care to stop rust. They work best in dry places. They are good where there is little corrosion.

Think about where you will use the flange. High pressure and heat need stainless steel. If you want to save money, carbon steel may be better.

Stainless steel flanges last a long time. They do not need much fixing. This saves money over many years. Carbon steel flanges may cost more later. You might need to repair them often.

Look at what your project needs. Think about the environment and your budget. This helps you pick the best flange type.

When you look at flanges, the material matters a lot. The metal inside each flange changes how it works and how long it lasts. It also decides where you can use it. Let’s look at what is inside each type.

A stainless steel flange is special because of its mix of metals. The main part is chromium. Every stainless steel flange has at least 10.5% chromium. Chromium makes a thin layer on the outside. This layer keeps the metal safe from rust and damage. It works even in hard places like chemical plants or near the sea.

Chromium is very important in stainless steel. There is no stainless steel without chromium. Chromium helps stop rust and damage.

Other things are in stainless steel flanges too:

Nickel makes the flange stronger and helps it fight acids.

Molybdenum gives more strength when it is hot and stops small holes from forming.

Carbon makes the metal harder, but too much makes it less bendy.

Manganese and silicon help make the steel strong and clean during making.

Some types you may see are a182-f304 and a182-f316. These have different amounts of nickel and molybdenum. This changes how well they fight rust and how strong they are in heat.

A carbon steel flange is made with a simple mix. It is mostly iron with some carbon. Sometimes, there is a little manganese or silicon, but not much else. Carbon makes these flanges strong and hard. More carbon makes them even stronger. But, it can also make them less bendy and easier to crack if hit.

More carbon in carbon steel flanges makes them stronger. This is good for high-pressure jobs.

More carbon can make them less bendy and tough. This can make them break easier.

You will see carbon steel flanges in places where rust is not a big problem. They are used in oil and gas pipes or water systems.

Here is a table to show the main differences:

| Material Type | Key Elements | Corrosion Resistance | Typical Applications |

|---|---|---|---|

| Carbon Steel Flange | Iron, carbon, small amounts of Mn, Si | Poor; rusts in wet/acid air | Oil, gas, water pipelines, low-corrosion environments |

| Stainless Steel Flange | Iron, chromium (≥10.5%), nickel, Mo, Mn, Si, C | Excellent; resists rust | Food, chemical, oil, gas, high-temp, corrosive places |

Stainless steel flanges always have chromium. This keeps them shiny and stops rust. Chromium makes a shield that blocks water and chemicals.

Carbon steel flanges have more carbon. This makes them strong but they can rust if not protected.

Stainless steel flanges often have nickel and molybdenum. These help them handle acids, salt, and heat better than carbon steel flanges.

Carbon steel flanges use simple metals. They work well for easy jobs but need more care in wet or tough places.

If you need a flange for tough chemicals or salty air, pick a stainless steel flange like a182-f304 or a182-f316. If you need something strong for a dry place inside, a carbon steel flange may be enough.

Stainless steel flanges are great at stopping rust. They have a thin, invisible layer on top. This layer keeps out water, air, and chemicals. You can use them where there is salt or harsh chemicals. They work well in places like the ocean. Stainless steel, especially grade 316, stays strong and shiny for years.

Here’s a table that shows how these materials do in salty places:

| Material Type | Corrosion Resistance |

|---|---|

| Stainless Steel (316) | High corrosion resistance, suitable for marine environments |

| Carbon Steel | Lower corrosion resistance, susceptible to rust and corrosion in harsh environments |

Experts use special tests to check for corrosion. They use Critical Pitting Temperature and Critical Crevice Temperature tests. These tests show if a flange can handle tiny holes or cracks from rust. Both tests follow the ASTM G48 standard. This helps you know if a flange will last in tough places.

Tip: Pick stainless steel flanges for places with lots of water or chemicals. They give the best protection from rust.

Carbon steel flanges do not stop rust as well. They can rust fast in wet or salty places. They are best for dry and clean areas. If you use carbon steel, you need to add paint or coatings. You also need to check and fix them often.

Engineers say to use carbon steel flanges in these cases:

Systems with medium or high pressure

Places with normal or high heat

Areas with little or no rust risk

Projects where you need to save money

Pipes in factories or power plants

Carbon steel flanges cost less, but they do not fight rust well. You need to think about where you will use them before you choose.

You should pick your flange based on where you use it. If you work near the sea or with chemicals, you need strong rust protection. Stainless steel flanges last longer and need less care in these places.

If your project is in a dry, clean spot, carbon steel flanges may work. But you still need to watch for rust and keep them in good shape. The best choice depends on how much rust protection you need and your budget.

Remember: Where you use your flange changes how long it lasts. Always check for water, chemicals, and salt before you pick your material.

When you pick a flange, you want it to be strong enough for the job. Mechanical strength tells you how much force or pressure a flange can handle before it bends or breaks. Both carbon steel and stainless steel flanges have good mechanical strength, but they are not the same.

Check out this table. It shows the minimum tensile strength for different flange grades. Tensile strength means how much pulling force the flange can take before it snaps.

| Grade | Minimum Tensile Strength (MPa) | Minimum Tensile Strength (psi) |

|---|---|---|

| F42 | 415 | 60,000 |

| F46 | 415 | 60,000 |

| F48 | 420 | 62,000 |

| F50 | 440 | 64,000 |

| F52 | 455 | 66,000 |

| F56 | 470 | 68,000 |

| F60 | 515 | 75,000 |

| F65 | 530 | 77,000 |

| F70 | 485 | 70,000 |

You can see that higher grades mean more strength. Stainless steel flange types like A182-F304 and A182-F316 also offer high mechanical strength, plus better resistance to rust.

Tip: If you need a flange for high-pressure or heavy-duty work, always check the mechanical strength first.

You might wonder how flanges handle heat. Temperature performance is important because some jobs get very hot. Stainless steel flanges work well in both hot and cold places. Carbon steel flanges can handle heat too, but not as much as stainless steel.

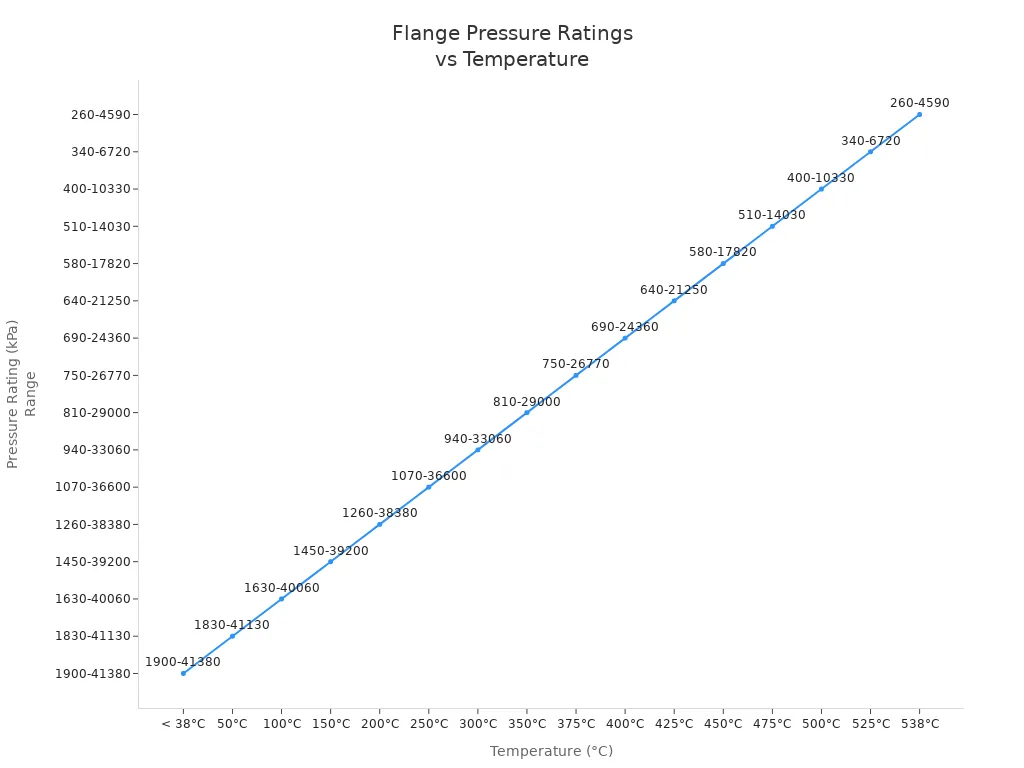

Here’s a chart that shows how pressure ratings drop as the temperature goes up:

If your system gets really hot, stainless steel flanges keep their strength better than carbon steel. This makes them a smart choice for steam lines or chemical plants.

Pressure ratings tell you how much pressure a flange can safely hold. Both types come in different classes, like 150, 300, or even 2500. Higher numbers mean the flange can handle more pressure.

| Pressure Rating | Maximum Working Pressure (psi) | Applications |

|---|---|---|

| 150 lb (150#) | 150 | Low-pressure systems |

| 300 lb (300#) | 300 | Moderate-pressure systems |

| 600 lb (600#) | 600 | Oil and gas transmission |

| 900 lb (900#) | 900 | High-pressure steam, petroleum refining |

| 1500 lb (1500#) | 1500 | High-pressure gas pipelines |

| 2500 lb (2500#) | 2500 | Extremely high-pressure applications |

You should always match the pressure rating to your system. If you use the wrong rating, the flange could fail.

Remember: Always check the mechanical strength, temperature performance, and pressure rating before you choose a flange. This keeps your system safe and running well.

When you look at flanges, price often comes first. Stainless steel flanges usually cost more than carbon steel flanges. You might pay double or even triple for stainless steel. This higher price comes from the special metals inside, like chromium and nickel. Carbon steel flanges use simpler metals, so they cost less. If you have a tight budget or need many flanges, carbon steel might look like the better deal at first.

You should also think about how much work each flange needs after you buy it. Carbon steel flanges need regular care. They can rust, especially in wet or chemical-heavy places. You may need to paint them or add a coating to keep them safe. Stainless steel flanges do not need much care. They resist rust on their own and keep their strength over time.

Here’s a quick table to show the difference:

| Flange Type | Maintenance Requirements |

|---|---|

| Carbon Steel | Prone to rust and corrosion; requires regular maintenance like painting or coating. |

| Stainless Steel | Minimal maintenance needed due to natural corrosion resistance; retains integrity over time. |

Tip: If you want less work and fewer repairs, stainless steel flanges make your life easier.

You might think carbon steel flanges save you money, but that is not always true. Over 20 years, stainless steel flanges often cost less in the long run. Carbon steel flanges need more repairs and sometimes full replacement every 10 years because of rust. Stainless steel flanges can last the whole time without needing to be replaced. Their durability means you spend less on repairs and downtime. When you look at cost and maintenance together, stainless steel flanges often win for big projects or harsh environments.

Stainless steel flanges are used where things must stay clean and safe. Food factories use them to keep food away from germs. These flanges help make cleaning fast and easy. They do not rust, even with lots of washing or strong cleaners.

Here’s how they help in food and drink factories:

| Application Type | Description |

|---|---|

| Processing Equipment | Keeps food clean and stops germs during making. |

| Pipelines | Moves food and drinks safely through pipes. |

| Storage Tanks | Stops rust and keeps food safe in tanks. |

Stainless steel flanges are good because they:

Stay clean and stop bacteria from growing

Do not rust, even with salty or sour foods

Can handle high heat and pressure

Do not break when temperatures change quickly

You will also see them in chemical plants and oil refineries. They are used in ships and other places near the sea. These flanges are strong, clean, and last a long time.

Carbon steel flanges are best when you need strength and a good price. Water plants use them to join pipes and stop leaks. You can take them apart for repairs and put them back easily.

Here is how carbon steel flanges help in water plants:

Make pipes connect tightly so they do not leak

Let workers fix and check pipes quickly

Spread out pressure so pipes do not burst

You will also find them in oil and gas pipes, buildings, and factories. They work well if rust is not a big worry and you want to save money.

When you pick a flange, think about your industry’s rules. Some places, like petrochemical plants, have strict rules like ASME and ANSI. These rules help you pick the right flange for safety.

| Flange Type | Advantages | Applications in Petrochemical Plants |

|---|---|---|

| Stainless Steel | Does not rust, lasts long, good for dangerous chemicals | Used for high pressure and very hot jobs |

| Carbon Steel | Strong and costs less, good if rust is not a problem | Used in oil pipes, building, and strong jobs |

Use stainless steel flanges if you deal with harsh chemicals or high heat. Use carbon steel flanges if you need strength and want to spend less. Always check your industry’s rules before you choose.

Stainless steel flanges have many good points. They last a long time and work well in hard places. You do not need to worry about rust. These flanges stop corrosion, so they are great in wet or salty spots. They stay strong when it gets hot. You can use them where there is high pressure or heat.

Here’s why stainless steel flanges are a smart pick:

| Advantage | Description |

|---|---|

| Corrosion Resistance | Stainless steel flanges resist rust, which is important for metal parts. |

| Durability | They are tough and can handle high pressure in factories. |

| Withstanding High Temperatures | They do not bend or change shape in very hot places. |

You will not spend much time fixing these flanges. They do not break down fast. You also save money on upkeep. If you want your system to be safe and work well, stainless steel flanges are a good choice.

Tip: Use stainless steel flanges if you have water, chemicals, or heat. You will be glad you did.

Carbon steel flanges help you save money, especially for big jobs. You get strong flanges for less money. They work well where rust is not a big worry. You can use them for a long time because they do not wear out fast. Their strength means you do not need to change them often.

Here are the main good points:

Cost-effectiveness: Carbon steel flanges work well and cost less.

Long-term durability: They are strong, so you do not replace them much.

Economic efficiency: They help you save money on big projects.

| Benefit | Description |

|---|---|

| Affordability | Carbon steel flanges cost less than other kinds. |

| Durability | They last a long time, so you do not need new ones often. |

| Reduced Maintenance | They are strong, so you do not spend much on repairs. |

If you want to spend less and still get good flanges, carbon steel is a good choice. You get strong parts without paying too much.

Note: Pick carbon steel flanges for dry, clean places or if you need to save money on a big job.

Picking the right flange can be hard. You want your system to be safe and work well. First, think about what your project needs. Ask yourself some questions:

Does your system get very hot?

Will your pipes have a lot of pressure?

Is rust or corrosion a big problem?

If you need flanges for hot jobs, stainless steel flanges are best. They do not rust, can take heat, and last a long time. Carbon steel flanges are good for high pressure, but they need help to stop rust. Here is a table to help you see the differences:

| Criteria | Stainless Steel Flanges | Carbon Steel Flanges |

|---|---|---|

| Environmental Factors | Stops rust and corrosion; works in hot and high-pressure places. | Can rust if not coated; good for high pressure. |

| Mechanical Properties | Has good strength and can bend without breaking. | Strong and tough; can be made even stronger with heat. |

| Cost Considerations | Costs more at first but saves money later. | Cheaper at first but may cost more to fix. |

Tip: If your job has heat, chemicals, or salty air, stainless steel flanges are a safe choice.

Where you use your flange and your money matter a lot. If your pipes are in a dry, clean place, carbon steel flanges can save you money. If you work near water, chemicals, or outside, stainless steel flanges protect your pipes and need fewer repairs.

Let’s see how the costs compare for city projects:

| Material | Initial Cost | Long-term Maintenance Cost | Durability and Longevity | Corrosion Resistance |

|---|---|---|---|---|

| Stainless Steel | Higher | Lower | High | Excellent |

| Carbon Steel | Lower | Higher | Moderate | Poor |

You pay more for stainless steel at the start, but you fix and replace it less. Carbon steel is cheaper at first, but you need to check and fix it more.

Note: Always pick a flange that fits your place and your budget. Think about how long you want it to last and how much work you want to do later.

You’ve seen how stainless steel flanges fight rust and work well with tough chemicals, while carbon steel flanges save you money for simple jobs. Check out this quick guide:

| Material Type | Best Use Case |

|---|---|

| Stainless Steel | Corrosive fluids, harsh environments |

| Carbon Steel | Non-corrosive, dry air applications |

Before you choose, ask yourself what your system needs. Here’s a checklist:

Will you handle high pressure or heat?

Do you need protection from rust or chemicals?

Is your budget tight?

New trends focus on eco-friendly and strong materials, so keep an eye out for those options. Pick the flange that fits your job and keeps your system safe!

Stainless steel flanges resist rust and weather. You can use them outside without worrying about rain or salty air. They last longer and need less care than carbon steel flanges.

Yes, you can paint or coat carbon steel flanges. This helps block moisture and slows down rust. You need to check the coating often and fix any damage to keep the flange safe.

Stainless steel flanges usually cost more at first. You save money over time because they need less fixing and last longer. If you want fewer repairs, stainless steel is a smart choice.

You should look at the pressure rating. Both types can handle high pressure if you choose the right grade. Stainless steel flanges work better in places with heat or chemicals.